Slip rings are essential components that enable the transmission of power and signals between stationary and rotating systems. One key factor in their performance and longevity is the choice of ring material. Common options include brass, bronze, and stainless steel (SS), each with distinct properties suited for specific applications.

Brass Rings

- Excellent electrical conductivity.

- Lower wear resistance compared to bronze.

- Cost-effective option for applications with moderate performance requirements.

- Low-speed operations.

- Applications with limited exposure to heavy mechanical stress or high temperatures.

Bronze Rings

- Superior wear resistance, making it ideal for demanding environments.

- Can handle higher mechanical loads and temperatures.

- Lower electrical conductivity compared to brass.

- High-speed and heavy-duty operations.

- Environments with abrasive conditions or high friction.

Stainless Steel (SS) Rings

- High resistance to wear, corrosion, and extreme environmental conditions.

- Lower electrical conductivity than brass or bronze.

- Requires compatible brushes (e.g., silver graphite) to minimize wear and ensure performance.

- Marine and offshore industries, where corrosion resistance is critical.

- Extreme environments with exposure to chemicals, high humidity, or temperature fluctuations.

Which Should You Choose?

- Performance Needs: For high-wear, heavy-duty tasks, bronze or stainless steel are preferred. Brass is more suitable for less demanding applications.

- Environmental Factors: In highly corrosive or extreme environments, stainless steel rings excel. Bronze works well under abrasive conditions, while brass is ideal for clean, low-stress settings.

- Electrical Requirements: Brass provides the best conductivity, followed by bronze. Stainless steel, while durable, has lower conductivity and requires specialized brushes for optimal performance.

- Cost Considerations: Brass is the most economical option. Stainless steel offers superior durability but comes at a higher cost, justified for critical applications.

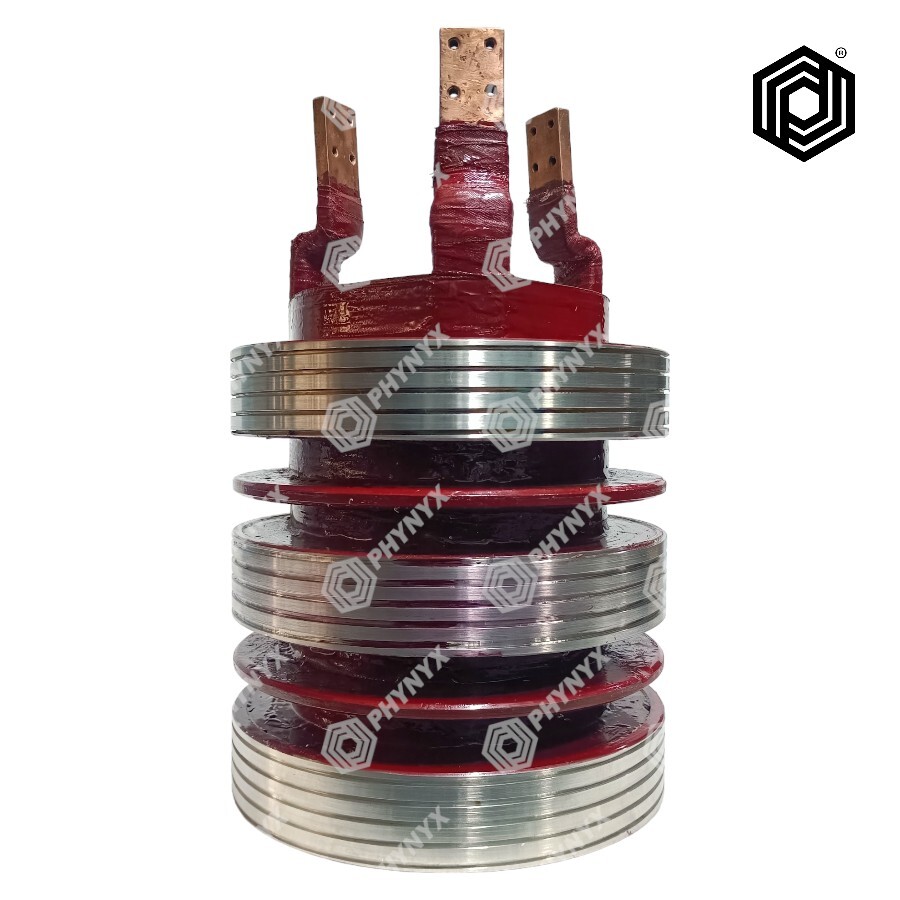

At Phynyx Industrial Products, we provide slip ring solutions with brass, bronze, and stainless steel rings, tailored to meet the diverse needs of industries. Our expertise ensures that you get the right material for your application, delivering exceptional performance, reliability, and value.

Need help selecting the right slip ring for your project?Contact us today, and our experts will guide you to the best solution for your requirements.