Phynyx - Your Leading Slip Ring Manufacturer and Supplier

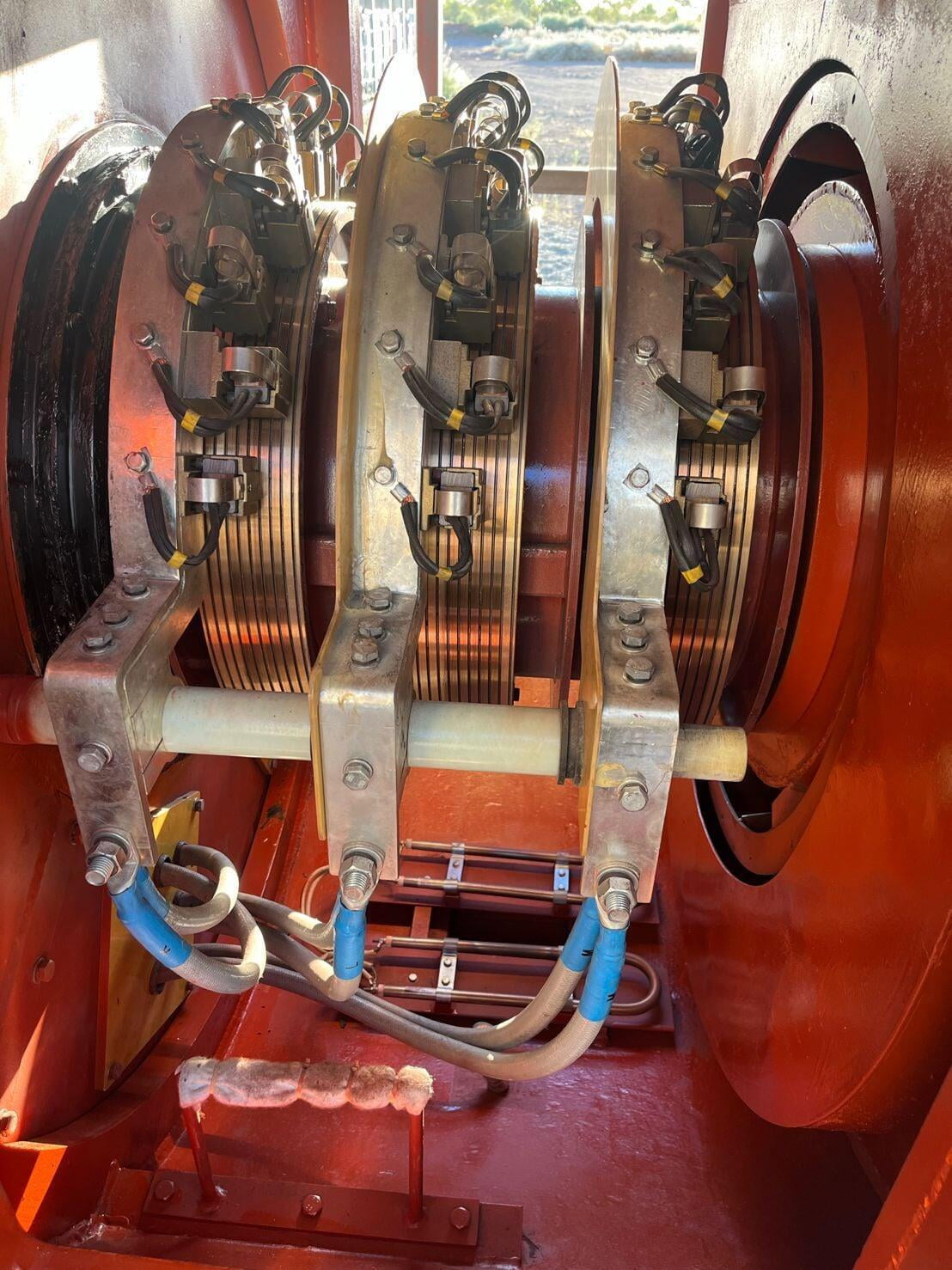

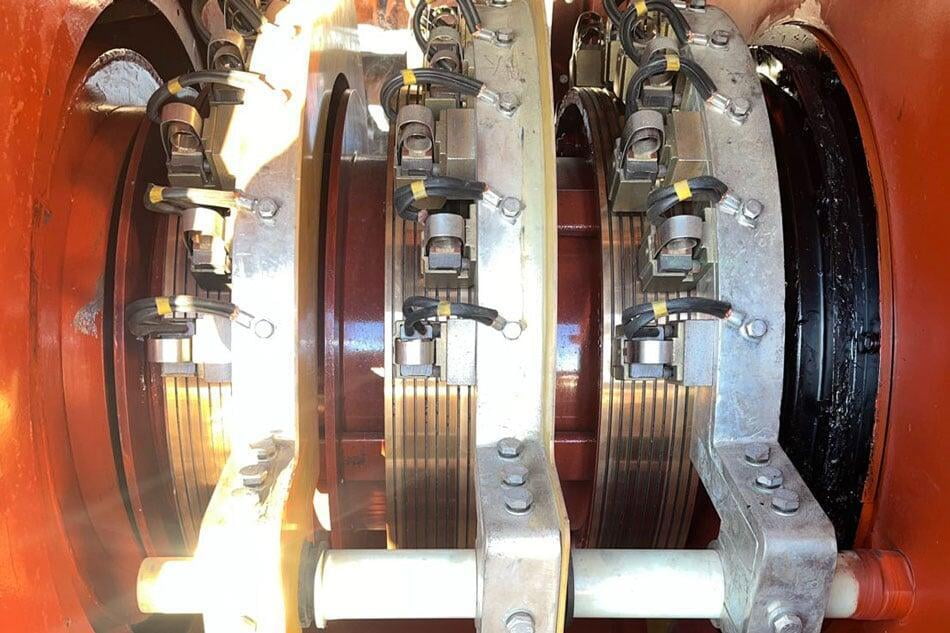

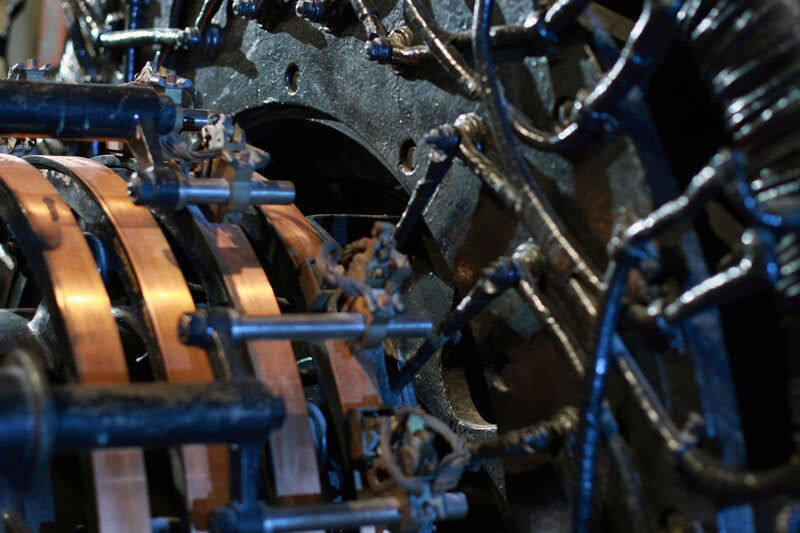

Elevate your machinery's performance with Phynyx Industrial Slip Rings, your trusted partner in seamless connectivity solutions. As a prominent slip ring manufacturer and supplier, we specialize in crafting slip rings that transmit power, electrical signals, and data flawlessly through 360° rotating joints in electrical devices. Our expertise extends to being a reliable replacement slip ring manufacturer, ensuring your operations never face interruptions.

Empowering Generators, Induction Motors, and AC Motors

Generators, induction motors, and AC motors are the lifeblood of numerous industries. Our slip rings play a pivotal role in transmitting power and control signals, ensuring seamless operation and precision in various industrial processes. Whether it's powering critical equipment, driving production lines, or ensuring efficient machinery performance, Phynyx Slip Rings are engineered to deliver unparalleled connectivity.

Precision for Wind Turbines

Wind energy demands reliability. Our slip rings are designed to endure the harshest conditions, ensuring uninterrupted power transmission between the stationary and rotating components of wind turbines. Phynyx Slip Rings play a crucial role in maximizing energy production and minimizing downtime.

Driving Electrical Motors

induction motors, and AC motors are the lifeblood of numerous industries. Our slip rings play a pivotal role in transmitting power and control signals, ensuring seamless operation and precision in various industrial processes.

Empowering Generators

Generators are the heart of power production. Our slip rings ensure efficient power transfer, enabling generators to function optimally. Whether it's a standby generator or a massive power plant, our solutions cater to various generator sizes and capacities.

Precision for Wind Turbines

Wind energy demands reliability. Our slip rings are designed to endure the harshest conditions, ensuring uninterrupted power transmission between the stationary and rotating components of wind turbines.

Why Choose Phynyx for Your Slip Ring Needs?

- Specialized Expertise: Our slip rings are meticulously crafted for specific applications, ensuring optimum performance across wind turbines, generators, induction motors, and AC motors.

- Durability in Design: Each slip ring is engineered to endure challenging conditions and provide long-lasting reliability.

- Tailored Solutions: Our solutions are customized to meet the unique demands of each application, empowering your machinery with the power of seamless connectivity.